Wire forms are used for many different purposes and have many different bend configurations based on the application. Wire forms can be designed to provide forces in applications where a deflection or torsional force is needed using high carbon spring steel, or where support or structure is necessary using low carbon steel. Typical designs for wire forms include linkages, torsion bars/rods, and wires. Linkages are products that require the need for two or more details to connect and work together to manage forces and movement. A torsion bar/rod is a wire form that provides torsional forces when one or both ends are rotated along the length of the part.

In terms of manufacturing, wire forms are most commonly manufactured from automated presses and hand bending equipment. At M & S Spring, we make your spring purchasing experience simple by providing you with accurate design input while meeting your demands for quality, price, and delivery. This is accomplished by using our customized Customer Order Management System (COMS) software, our spring design software, and specialized spring manufacturing equipment.

.jpg)

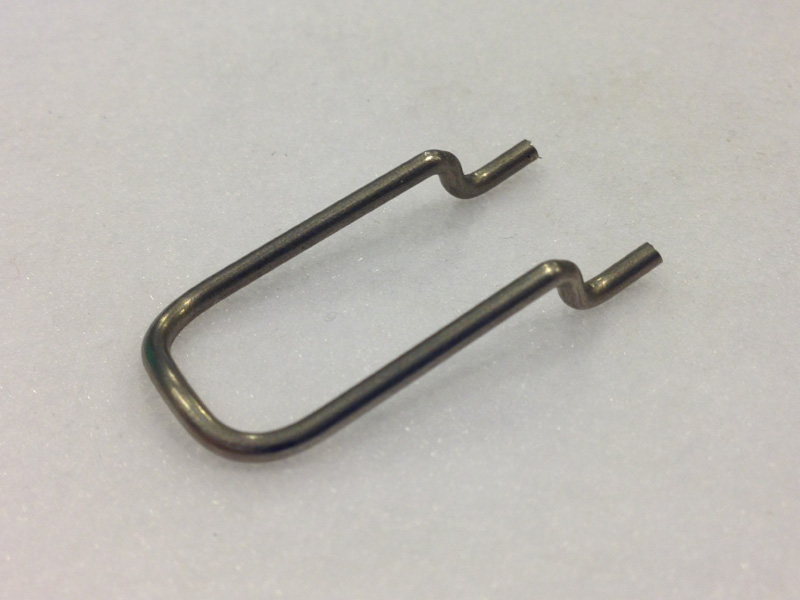

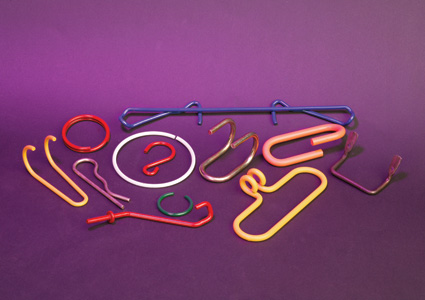

Wire Form Applications

While most industries utilize wire forms, there are common applications where wire forms can be found such as:

- Torque rods/bars

- Electrical applications

- Hooks

- Structure support (plastics)

- Connectors

Sizes Offered

Steels that are most commonly used in our process for manufacturing wire forms are either low carbon cold rolled steel or high carbon spring steels such as Oil Tempered, Chrome Silicon, Music, and Stainless Steel wire. Our manufacturing capacity for wire forms ranges in wire diameters from .010” up to .500”, with many of our prototype and short-run orders ranging from these sizes. We can supply wire forms with a variety of special finishes or coatings to your specification.

Below details the common materials and grades that we work with, but if the material needed for your project isn’t listed, please feel free to fill out a quote today!

Round Wire

| Material | Grade | Specification | Request A Quote |

|---|---|---|---|

| High Carbon Spring Wire | Music Wire | ASTM A228 | |

| Hard Drawn | ASTM A227 | ||

| Oil Tempered | ASTM A229 | ||

| Alloy Steel Wire | Chrome Silicon | ASTM A401 | |

| Chrome Silicon Valve | ASTM A877 | ||

| Stainless Steel Wire | 302 | ASTM A313 (AISI 302/304) | |

| 316 | ASTM A313 (AISI 316) | ||

| 17-7 PH | ASTM A313 (631) | ||

| Non-Ferrous Alloy Wire | Phosphor Bronze | ASTM B159 | |

| Beryllium Copper | ASTM B197 | ||

| Brass | ASTM B134 | ||

| Copper | ASTM B152 | ||

| High Temperature Alloy Wire | Inconel 600 | ASTM B166 | |

| Inconel x750 | AMS 5698, 5699 | ||

| Special Purpose Alloys – Wire | Elgiloy | AMS 5833 | |

| Low Carbon Spring Wire | Cold Rolled Steel (CRS) | ASTM A510 / ASTM A853 |

Wire Form Gallery